In effect, we have created leaders, who then continue to strengthen our leadership position in the market place.”īrady Muller | Service Process Manager & Lean Champion We have developed a performance culture that gets results for the benefit of the company and our customers. If the team can think critically when approaching problems, and those problems are resolved effectively, we have done more than simply problem-solve.

#TOYOTA LEAN MANUFACTURING HOW TO#

Toyota Lean Management is a management philosophy that teaches team members how to solve problems in a way that is effective and sustainable.īy surfacing the problems and then thinking through how to solve the problems, we teach the team how to think and take responsibility. If the execution of the counter-measure is appropriate but the results are not where we need them to be, we adjust the counter-measures along the way, restarting the PDCA cycle. The PDCA cycle ensures that counter-measures are being implemented correctly. Who will follow up with a by-when, is crucial in the Plan-Do-Check-Adjust cycle. Ohno, Taiichi (2007), Workplace Management."Once we have created the counter-measures to address the problems, we also decide upfront how we will monitor their implementation.Ohno, Taiichi (1988), Workplace Management, Productivity Press, ISBN 0-91.Ohno, Taiichi (1988), Toyota Production System: Beyond Large-Scale Production, Productivity Press, ISBN 0-91.The point is whether one can exercise it. Re-improve what was improved for further improvement.Valueless motions are equal to shortening one's life.

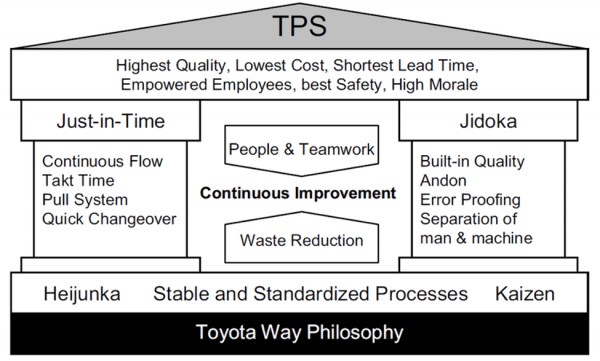

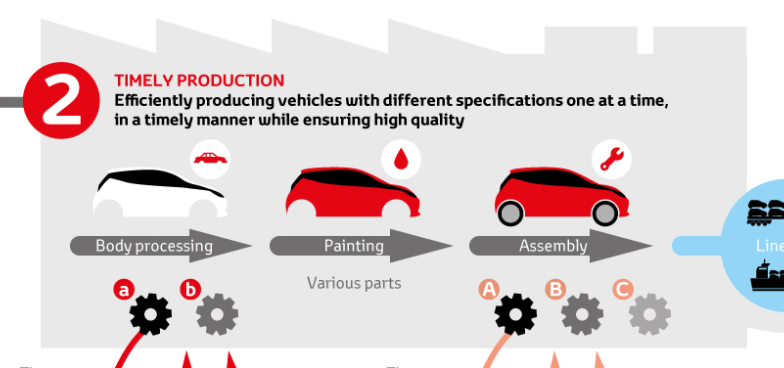

Repeat things that are easy to understand. Explain difficult things in an easy-to-understand manner.Once you start something, persevere with it.Starting something right now is the only way to win. You can find answers only in the workplace. First say, "I can do it." And try before everything.Ohno is also known for his "Ten Precepts" to think and act to win. Over processing or undertaking non-value added activity Delay, waiting or time spent in a queue with no value being addedģ. Ohno was also instrumental in developing the way organizations identify waste, with his "Seven Wastes" model which have become core in many academic approaches. For example, the field of sales process engineering has shown how the concept of Just In Time (JIT) can improve sales, marketing, and customer service processes. Ohno's principles influenced areas outside of manufacturing, and have been extended into the service arena. He moved to the Toyota motor company in 1943 where he worked as a shop-floor supervisor in the engine manufacturing shop of the plant, and gradually rose through the ranks to become an executive.

He wrote several books about the system, including Toyota Production System: Beyond Large-Scale Production.īorn in 1912 in Dalian, China, and a graduate of the Nagoya Technical High School ( Japan), he joined the Toyoda family's Toyoda Spinning upon graduation in 1932 during the Great Depression thanks to the relations of his father to Kiichiro Toyoda, the son of Toyota's founding father Sakichi Toyoda. He devised the seven wastes (or muda in Japanese) as part of this system. He is considered to be the father of the Toyota Production System, which inspired Lean Manufacturing in the U.S. Ohno Taiichi ( 大野耐一, Ōno Taiichi, Febru– May 28, 1990) was a Japanese industrial engineer and businessman.

0 kommentar(er)

0 kommentar(er)